Basic properties:

grammage, thickness, moisture, Density

Strength properties:

tensile and tearing strength, elongation

Surface properties:

brightness, opacity, whiteness,

smoothness/roughness, surface strength

Absorption properties:

water, oil, printing ink

Basic properties

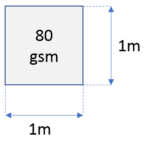

• Grammage:

Grams per Square Meter (g/m²)

• Thickness:

The distance between two surfaces of the paper sheet is measured in micrometers (μm).

• Moisture:

The moisture level is measured using relative humidity (RH), and most papers are designed to remain stable at 45-55% RH at a temperature of 72 degrees Fahrenheit. Typically, paper manufacturers produce paper with an absolute humidity between 4% and 8%, meaning that water constitutes 4% to 8% of the total weight of the paper.

• Density:

It explains the paper’s compactness, which is measured in kilograms per cubic meter (kg/m³).

Density (kg/m3) = ( grammage (g/m2)x 100 ) / ( thickness (μm) )

Strength properties

• Tensile:

The tensile strength of a material is the maximum mechanical tensile stress it can withstand before fracturing. It is typically expressed in N/mm² or MPa.

• Tearing strength:

The rupture strength of a material, also referred to as tensile strength at the moment of rupture, is the mechanical tensile stress at the point of fracture. It is also given in N/mm² or MPa. Since the maximum tensile stress and tensile strength at the moment of rupture are typically the same for elastomers, these two terms are often used interchangeably.

• Elongation:

Elongation at break is a characteristic value that describes the maximum percentage of elongation experienced by a tensile specimen at the moment of fracture. Therefore, it characterizes the deformation of a material under tensile load.

Surface properties

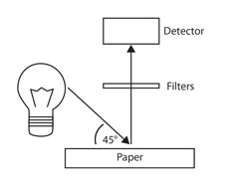

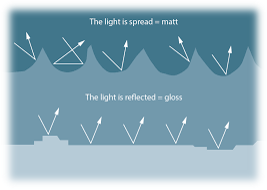

• Brightness:

Brightness measures the amount of reflection of a specific wavelength of blue light. Brightness is measured on a scale of 0 to 100 – the higher the number, the brighter the paper. In other words, paper with a brightness of 95 reflects more light than paper with a brightness of 85, making it appear brighter.

• Opacity:

Opacity is a measure of a paper’s ability to prevent light from passing through the sheet. Opacity of paper determines whether text or graphics on the opposite side of the paper are visible or not.

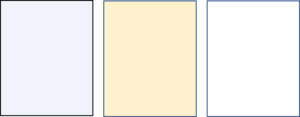

• Whiteness:

This characteristic pertains to the measurement of all visible light that is reflected from the surface of a paper sheet, which is a combination of all wavelengths of white light, hence earning its name. Since this parameter calculates the white light reflected from the paper’s surface, it expresses the paper’s whiteness in relation to brightness. Whiteness affects the appearance of color in a printed image. Whiteness is measured on a scale of 1-100%. Generally, selecting a whiter/whitest paper is straightforward, at least under controlled lighting conditions. When visually assessing whiteness, any glossy coating should be taken into consideration as it alters the appearance of paper with added reflectivity.

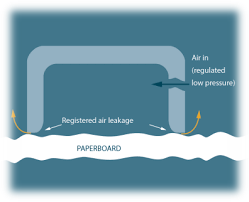

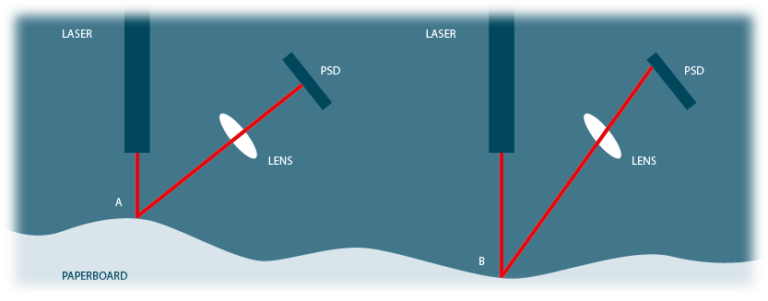

• Smoothness/Roughness:

Surface smoothness and surface roughness tests help you determine whether a surface is suitable for a specific purpose or not. These crucial tests demonstrate the role that surface roughness of materials used in manufacturing your products plays in their durability and performance.

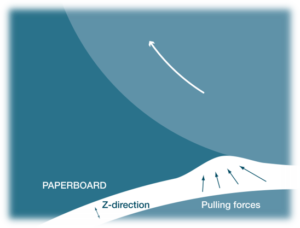

• Surface Strength:

Surface strength in this context refers to the ability of the paper’s surface to withstand tensile forces, thus preventing delamination or lifting of the printed surface or both. A common test method for evaluating surface strength is the IGT printability test.

Absorption Properties

• Water Resistance:

Some thermal roll papers come with a water-resistant coating or treatment. This coating helps protect the paper from moisture, spills, and humidity, making it suitable for applications where exposure to water is a concern, such as in restaurants or outdoor settings.

• Oil Resistance:

Thermal paper can be designed with barrier properties to resist the penetration of oils or grease. This is especially important in applications where the printed material may come into contact with oily substances, such as kitchen order tickets or food labels.

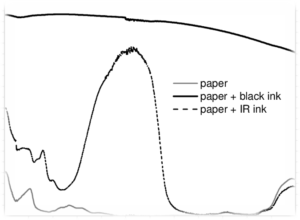

• Printing Ink Compatibility:

- Thermal Printing: Thermal roll paper is primarily designed for thermal printing, which means it is heat-sensitive and doesn’t require traditional ink or toner. The paper is specially coated to react to heat from the thermal printhead to create prints.

- Direct Thermal vs. Thermal Transfer: There are two main types of thermal printing: direct thermal and thermal transfer. Direct thermal printing uses paper with a heat-sensitive coating that darkens when heated. Thermal transfer, on the other hand, uses a ribbon coated with ink that is transferred to the paper when heated. It’s essential to choose the right type of thermal paper for your specific printing method.

The Other Thermal Paper Properties

- Image stabilityrefers to how many years the thermal print will be readable when stored in correct conditions.

- Image Density is an optical density value measured from thermal printed image.

- Static sensitivityshows at which temperature the thermal image starts to formulate. Low static sensitivity means that the thermal image starts to formulate at high temperatures. High static sensitivity, in turn, means that thermal imaging starts at low temperatures. If thermal paper is used at high-temperature conditions, the static sensitivity is a very significant feature.

- Dynamic sensitivity shows how fast and with what energy level the thermal paper can be printed. Basically, higher dynamic sensitivity equals better quality.